Buying old or new car, we do not think requiring noise insulation. Just as buying an apartment, don't think about it insulation. But sometimes it is just a necessity of life.

The same car brand in Europe and on the Ukrainian roads will be different to go. The ride quality is affected by road surface. Potholes can accelerate the wear of the car, worn shock absorbers, increases the noise in the cabin during the trip. Also, during operation of the engine vibrations that cause squeaks and my dogs. Noise can arise from the transmission, and poor quality plastic interior parts.

To eliminate unnecessary sounds are used two types of materials: sound insulation and vibration control. One material without the other is not a complete isolation of the car. The necessary materials are laid in two or three layers. It is better to use a self-adhesive material, it will speed up and simplify the installation process.

To eliminate unnecessary sounds are used two types of materials: sound insulation and vibration control. One material without the other is not a complete isolation of the car. The necessary materials are laid in two or three layers. It is better to use a self-adhesive material, it will speed up and simplify the installation process.

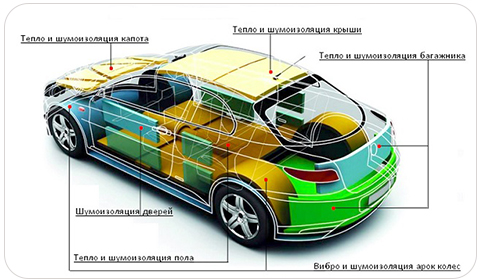

The only main caveat that all sound insulating materials affect weight gain details. So no need to do a lot of insulation layers, because the effect of suppressing noise such manipulation will not improve, and weight will be added. Without fanaticism, as they say. Depending on requirements it is possible to shumoizolyatory the whole car or one of the following sections: doors, ceiling, floor, wheel arches, trunk.

The effect of noise reduction depends on a proper choice of the material and its installation. Universal and single option no insulation, so for the absorption of noises and sounds using several types of materials, which include:

1. The vibration damper absorbs the vibration and converts the energy from mechanical into thermal. That is, reduce vibrations and metal. From this material do the first coat in the car. It consists of bitumen or butyl rubber. The principle of operation of VIBROCONTROL – heavier metal of the machine. Sold with adhesive base, which when mounting is pre-heated with a Hairdryer. It is used for wheel arches, ceiling panels and doors and parts separating the passenger compartment from the compartmentwhere the motor is.

Vibrocenter cope with sound waves from 20-500 Hz. They are applied on the metal coating. The thickness of the material is selected based on the thickness of the body. You can buy a vibration damper with Fuliginous layer. A lack – the big weight. After a while can SAG a door treated with this material.

Use for ceiling thickness from 1.5-2 mm, trunk and door are not more than 2 mm, the floor and wheel arches not less than 4 mm, shield motor from 3-4 mm.

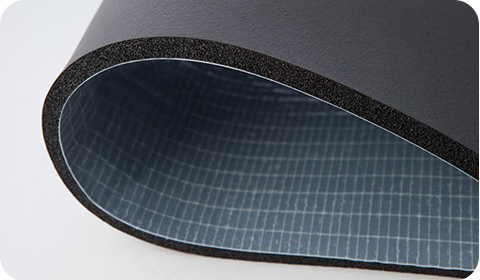

2. Insulation use foamed rubber, which reduces mid and high frequencies. Assemble the second layer after the vibration damper. Reduces external noise. They also insulated the hood of the car. Serves as a barrier to vibration, suppress it to a minimum. The material is flexible and elastic, easy to stow in the cabin and boot. The thickness is adjusted depending on the gap between the skin and the treated section.

For the ceiling and doors suitable thickness - 1.5 cm, on the floor from 6 mm to 1 cm Insulation designed for interior work in the cabin. It reflects the sound waves and prevents them to penetrate inside. Has moisture resistance and vapor resistance, provide reliable protection for floors and doors.

Foam rubber great used for soundproofing of the car. A closed cell structure eliminates the noise. It is quite flexible and therefore suitable for uneven areas of the car.

For good sound insulation does the thickness of 9 mm.

To benefits can also include:

- fire safety

- reduced noise and vibration

- heat retention

- vapour resistance

- easy to assemble

- elastic

- withstands temperatures from -200 to 105ºC

We have for sale is Oneflex rubber foam with a thickness of 6 mm, 9 mm, 13 mm, 19 mm, 25 mm, 32 mm. the Base is self-adhesive (allows you to glue the material and do not use a mounting dryer) or without adhesive layer, plain or with aluminum coating. The presence of aluminum layer has a positive effect on the insulating properties. The sale is from 1 m2. Rubber of 9 mm helps to get rid of structural noise and sound. The rubber is too thick (19 mm to 32 mm) is not worth taking, because in combination with other soundproofing materials will greatly increase the weight of the machine. Can SAG doors and reduced maneuverability.

Glued the rubber should be treated with a roller from the center of the material toward the edges to avoid bubbles.

The noise level of 84.7 dB, the thickness of rubber of 6 mm reduces the noise of 10.4 dB with sound absorption 9mm from 12.8 dB!

3. Silencer – polyurethane foam which has an open cellular structure of a certain size and treated with special impregnation. Cells are placed randomly apart from each other. Most often used as cushioning material due to its plasticity and the possibility of compression. High demand thickness: 2 mm, 4 mm, 8 mm. working Principle: the middle and high audio frequencies, once it gets into the foam attenuates the vibrations of the sound waves due to the transition from one cell to another. It is used for insulation of doors, roof and joints.

Prepare the surface and degrease. Also very effective for noise isolation plastic parts. Glue the top layer of vibration isolation. Improves acoustics and reduces vibration. When placed on the ceiling of the cabin, removes the condensate.

4. Antislip is a thin jointing material used for insulation joints of panelsthat creak and winding wires.

Insulation carried out in several stages:

- the entire compartment or part of the machine, which will isolate completely dismantled. Cleaned and dried the inner part of the body.

- then completely or partially removed avtozavodskii insulation materials (for example: if they have peeled off or there is swelling of the material).

- surface is degreased. This is important because the correctness of the performed work depends on how well glued material. For degreasing you can take white spirit.

- after the sheet insulation is cut and paste form. At the temperature of 25ºC, the adhesive should be heat circuit dryer.

- make the Assembly of parts in reverse order.

Through car doors and plenty of outside noise. Doors almost any machine, though the price and brand, have poor sound insulation. Therefore, sumasayaw this part, much reduced noise in the car. Also for lovers of good sound, at times to improve the acoustics. When a large area of the bonnet, receives vibration from the engine to other parts of the machine. The isolation of this zone will decrease the noise level in the cabin.

For sound insulation of a floor will need to remove front and rear seats. After removed the plastic plate attachment from the carpet to the floor, then removed the carpet. Cleaned and degreased metal surface. The first layer is superimposed vibration. Surface treated roller. If this is not done, there are air bubbles, which will be condensation and this will further lead to rust. Vibration isolation is better to take not more than 4 mm, because it is necessary to consider also the thickness of the carpet. Sound insulation is recommended to take 9-10 mm, it is applied as the second layer. When these two layers is laid, the surface is treated again with a roller. Then placed the trim and all the removed parts in reverse order.

The tools you will need:

The tools you will need:

- roller for rolling the material

- a knife or scissors

- mounting dryer

- carob keys

- tools trim removal

- degreaser

- gloves

If you want to save, make a noise one or more zones of a car, but not the whole car. If you stick this material only for door cars, you will be able to experience significant positive changes. But with a strong desire, if you want to fully insulate the car better to contact the experts, because they will be able to solve this problem. Thanks to noise isolating you'll be less distracted by extraneous noises and chatter will cease to be irritated and begin to enjoy the lack of extra sounds.

Thanks to the sound insulation improves the sound of the system, and improving the insulation of the car, an additional corrosion protection. Insulation machines can run two to three days. Better to work indoors, you will not be tied to weather and natural light.