AISI 201 and AISI 304 alloys are similar in many ways, and many mistakenly believe that AISI 201 is a cheap analogue of AISI 304, and there is no significant difference between these two steels. In fact, the situation is somewhat different. We have prepared for you a comparative characteristic of alloys, which will clearly show what the difference between the two brands is.

Chemical composition

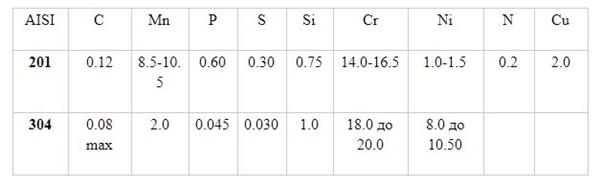

First of all, the difference in the price of these alloys is caused by a different chemical structure, which, in turn, directly affects the physical characteristics and operational qualities.

As can be seen from the table, the nickel and chromium content in alloy 304 is significantly higher than that of the budget AISI 201, which causes greater resistance to corrosion of the first of the alloys. Alloy 304 is considered one of the most commonly used grades of austenitic grade steels. At its price, this alloy gives high oxidation resistance, high-quality performance properties and good weldability. The alloy is acid-resistant, short-term exposure to high temperatures up to 950 degrees is acceptable.

AISI 201 contains manganese, nitrogen, nickel, chromium in balanced proportions.

The structure of the alloy is stabilized by adding nitrogen to the composition, which, by the way, reduces the content of other stabilizers - nickel, manganese. Steel has high mechanical resistance, there is a potential for cold deformation. AISI 201 is moderately welded, susceptible to deep drawing.

Technological features

- AISI 201 is easy to forge, hardens during cold deformation. It is well processed in a cold state. It is characterized by strength during stamping, bending, stretching. It is welded by arc welding, retains plasticity during drawing, thanks to the copper in the composition.

- AISI 304 requires annealing in any hot treatment, it is considered very durable, elastic and a plate. Suitable for rotary and deep drawing, bends well, can be molded by stretching. Welding is characterized as good.

Alloy 201 does not have high corrosion resistance under aggressive external influences. Accordingly, it is advisable to use this steel as a material for parts used indoors under the condition of normal humidity and temperature.

In turn, 304 alloy on the contrary has high corrosion resistance and oxidation resistance, therefore it is widely used to create equipment, parts, pipelines, handrails installed in an aggressive environment.

Scope of application

Alloy 201 is widely used in mechanical engineering, the aviation industry, to create pipeline parts where contact with aggressive substances is not expected. Often 201 alloy is used in the food industry (without contact with food), furniture production, the creation of household items. Handrails and fences inside buildings, ramps and other special structures are made of AISI 201.

Alloy 304 is used in various fields of light and heavy industry, in domestic conditions, in medicine as a material in contact with aggressive environments. It is suitable for contact with food products, therefore, containers for water and bulk substances are made of 304. The high corrosion resistance of the material makes its scope of application much wider than that of alloy 201. AISI 304 can be found in public swimming pools and saunas - handrails and fences are made of this alloy.