What is vibration isolation?

Vibration is a complex of measures aimed at protection of buildings, equipment and people from the harmful effects of vibration by introduction of intermediate elements between the vibration source and the protected object.

Vibration is a complex of measures aimed at protection of buildings, equipment and people from the harmful effects of vibration by introduction of intermediate elements between the vibration source and the protected object.

Railways, as a rule, are sources of excessive vibration and structural noise in buildings located in the immediate vicinity of tracks and railway stations. Urban transport covers railway and underground transportation and is determined by axle load up to 13 metric tons and a maximum speed of 100 km/h. the Main problem for urban rail transport is the surrounding area is noise sensitive. In this article I propose to consider the ideal solution to effectively minimize vibration and noise in urban areas caused by rail traffic, trams and metro. Vibration with small attenuation spread on the ground over long distances, creating air noise in the rooms located even at a considerable distance from the noise source.

Every year due to urbanization, large parts of the track in contact directly with the cities, becoming one of the cities next to them there are more and more modern residential complexes with infrastructure - hospitals, office buildings, shopping centers, concert halls, cinemas. In conditions of market competition and the fight for customers, the requirements for acoustic comfort also become more stringent.

In this article we will discuss protective measures for reducing structural noise and vibration isolation of Foundation from the new generation material – Sylomer.

Sylomer is an elastic material made of foamed polyurethane with a mixed cell structure.

Due to the distinctive characteristics, the elastomer can solve a wide range of applications for vibration isolation of foundations in the vicinity of the railway, tramway and metro:

- resistant to all weather conditions, various oils and greases, acids and paint and other chemically active substances, carried by railway;

- can withstand over 2 million cycles of stress;

- resistant to overloads;

- retains its elastic properties over a long period of years under the influence of constant loads that affect the movement of trains and near the Foundation.

Material Sylomer is also applied as an elastic element in the vibration isolation of building foundations, vibration isolation in piping, heating systems, air ducts, water and air, in the device ties, etc. depending on load and destination and the device design is chosen for a specific model Sylomer.

To protect from vibration and reduce structure-borne noise during the construction of foundations of buildings near Railways in Europe and the US use an elastic support. The installation of the building on a flexible support of elastomer Sylomer is one of the most efficient and reliable solutions for vibration isolation of Foundation.

Why in the design, construction, reconstruction of foundations, in the construction or repair of railway tracks of European and American experts choosing this material:

- durability (endorsement of the Munich technical University material Sylomer without fear can be used for 100 years for the purposes of vibration isolation of buildings from rail tracks from the point of view of material fatigue due to dynamic loads)

- a wide range of static loads for the materials Sylomer from 0,011 N/mm2 1.2 N/mm2

- temperature resistance (Sylomer withstands temperatures from -30 º C to 70 º C).

- chemical stability (the material is characterized by resistance to any aggressive media, diluted acids and alkalis, various oils, greases and other chemical agents)

Depending on the long-term static load acting on the elastic layer corresponding to the selected type of material of the standard Sylomer range of materials Sylomer SR. The thickness of the layer of elastomer for elastic support is selected depending on the required effectiveness of vibration isolation of the Foundation. The greater the thickness, the lower is the ratio of the frequencies, and consequently improves the efficiency of the system as a whole. Polyurethane elastomer Sylomer, speaking in plain language, it is the equivalent of spring combined with the damper. Depending on the type of damping material is from 7% to 11%.

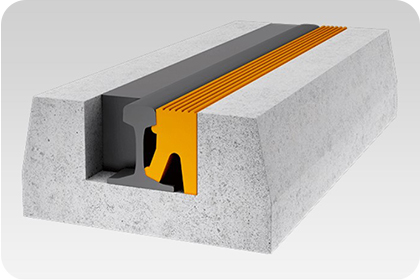

Sylomer (dynamometer) is the most suitable elastomer for use in the superstructure of railway tracks.

More than 20 years, the materials Sylomer used in Railways and rail transport in cities for effective protection against vibrations and structure-borne noise.

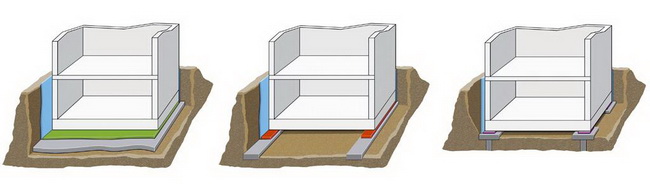

Structurally, the elastic supports may be poluploskosti, tape or spot and are mounted directly on the building foundations.

|

Poluploskosti bearing Belt bearing Point support |

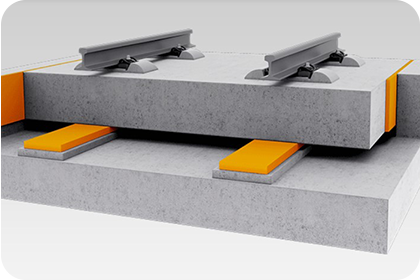

In a situation when you need to vibroisolating the Foundation of buildings located near the railroad, but directly the base rails are used elastic support of the same species.

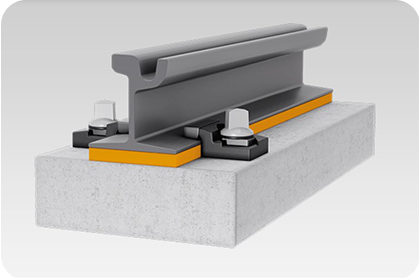

Elastic supporting members support characteristics of the load distribution on the rail and reduces vibrations caused by unevenness of wheels and rails. The deflection of the rail during the passage of trains can be reduced by adapting the distribution of the rigidity of the base plate of the cushion.

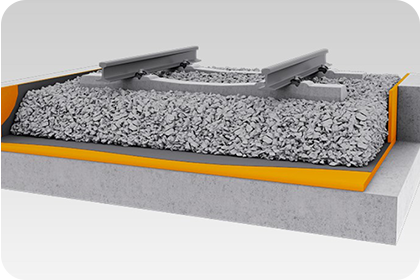

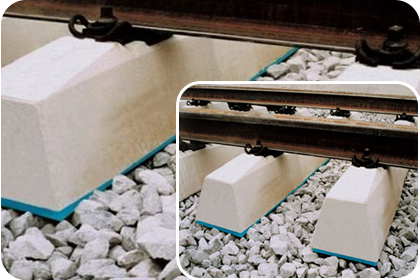

Due to the material sleeper (support rail, made of timber or reinforced concrete) is elastically supported on the ballast layer of the track structure and ensure the long term permanence of the mutual arrangement of rail lines and reducing the level of vibration.

Due to the material sleeper (support rail, made of timber or reinforced concrete) is elastically supported on the ballast layer of the track structure and ensure the long term permanence of the mutual arrangement of rail lines and reducing the level of vibration.

To achieve high levels of vibration the natural frequency of the structure on elastic supports must be properly designed.

Material Sylomer is flexible and convenient to fit to the base when laying effortlessly. The stiffness of the applied material increases with increasing density (volume weight) and the determined applied load.

The material is laid on a prepared and leveled surface. The surface must be without recesses and projections. Concrete surface rough to wipe or adjust. The maximum allowable size of the roughness is determined by the thickness of the material of the support.

For supports with a thickness up to 25 mm permissible roughness - up to 3 mm, for poles of 25mm above - surface irregularities shall not exceed 5 mm. For pillars with thickness less than 8 mm require higher quality treatment of the basics!

Sylomer is often placed just on the surface without additional fixing, however, in some cases, the material must be glued. For this purpose, the adhesive surface of two-component polyurethane adhesive or adhesive bitumen based.

The support of Sylomer materials possess distinctive properties of long-term strength and do not need maintenance for the entire period of operation, access after installation for maintenance or subsequent replacement is not required.

Railways and urban areas are becoming closer neighbors. Vibration and structural noise generated by the Railways, have a negative impact on residents and buildings near train, tram tracks and metro lines. Our materials increase the elasticity of the railway superstructure. This leads to less wear of components of the superstructure, such as rails, sleepers and ballast. The carefully chosen materials of maintenance costs and life cycle costs of Railways, tramways and metro lines are significantly reduced. Technical solutions Sylomer was developed for vibration control of the railway to cope with all the axle loads and speeds and for vibration isolation of foundations of buildings and structures near the tracks. They are used worldwide and are the leading products in the railway sector.

Railways and urban areas are becoming closer neighbors. Vibration and structural noise generated by the Railways, have a negative impact on residents and buildings near train, tram tracks and metro lines. Our materials increase the elasticity of the railway superstructure. This leads to less wear of components of the superstructure, such as rails, sleepers and ballast. The carefully chosen materials of maintenance costs and life cycle costs of Railways, tramways and metro lines are significantly reduced. Technical solutions Sylomer was developed for vibration control of the railway to cope with all the axle loads and speeds and for vibration isolation of foundations of buildings and structures near the tracks. They are used worldwide and are the leading products in the railway sector.

Solutions from material Sylomer not only effectively reduce vibration and will enhance the quality of life in homes and work environment in the offices in the immediate vicinity of these facilities, please contact us!